It took 5 years to remove the plastic cap, here’s why..

It’s been an incredibly tough journey to change the design of our packaging. I’ve always wanted to get rid of the plastic lid that comes as standard on all of our smoke products. I’ve always thought it unnecessary, but in the world of red tape, certified approvals and strict transport classifications, the black protective cap was always deemed necessary..

In hindsight the latest packaging seems blatantly obvious, but let’s not go there right now.

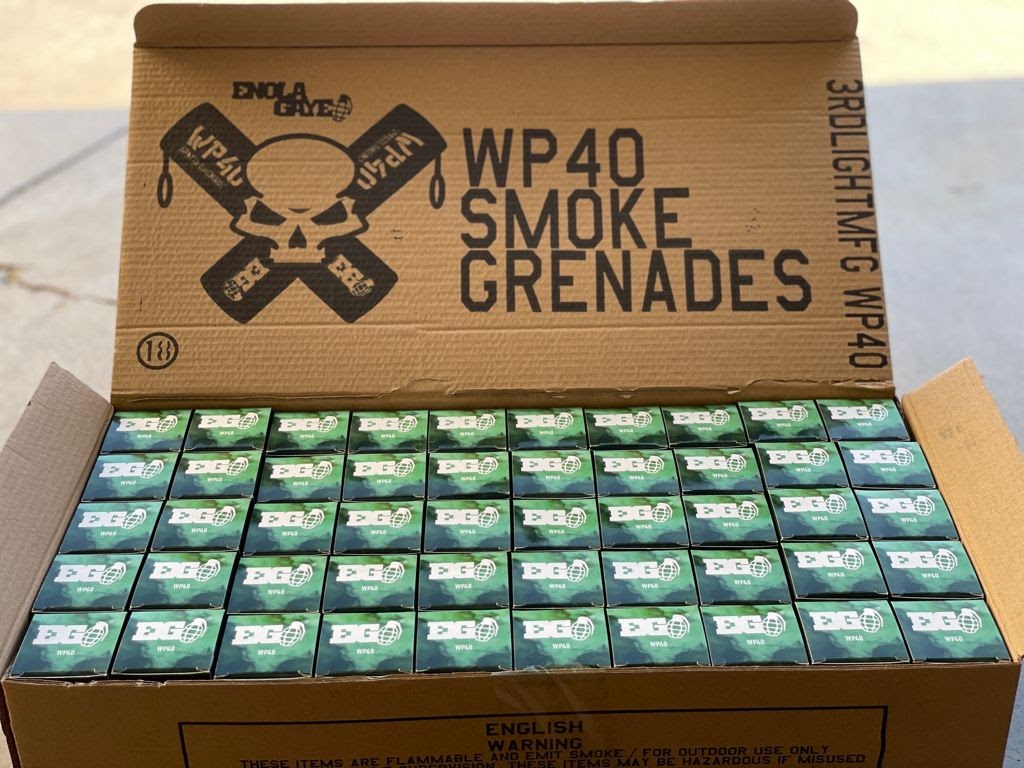

We’ve finally removed the plastic cap and the units are packaged in cardboard boxes as pictured. Why was this so hard? If you’re interested read on, otherwise stop here as the main message has been relayed. Packaging has changed.

When a product is designed that requires specialist transport, it has to pass many tests to ensure it is safe for transport and that information is registered by different government authorities around the world. Should you want to change the design, well that’s kinda starting again.

How confident would you be if you dropped a full case of products you designed from 10 meters? The point being that there are no ignitions and the product still needs to function properly afterwards. It’s a messy nail biting experience, knowing you may have to go back to the drawing board.

Without going into too much detail, this is one of many tests to enable us to place it in the hands of users. Make changes to that design and its, do it all again, no shortcuts here…

The project to reduce plastics in our products started 5 or so years ago and with all things considered we have finally made it happen. It’s not a new product, it’s the trusted WP40 smoke with the cap removed and a biodegradable box for packaging.